3PL WMS Buyers' Guide

You’re consistently responding to customer RFPs. Get that data together and look at your custom capabilities and requirements. If you specialize in an industry or are a great fit for a customer of a specific size, add it to your notes.

The more you can have in front of you for 3PL distribution and WMS requirements conversations, the better. Remember that every 3PL warehouse is built to serve customers outside of the business itself.

You’ve been flexible and smart over the years, and it’s right to expect a 3PL WMS vendor to do the same for you.

Now, let’s get into the most important questions for you to answer as you start this process. We'll cover:

- What is a 3PL warehouse management system (WMS)?

- What are your 3PL WMS requirements?

- How to gather your 3PL WMS requirements

- What features should you look for in a 3PL WMS?

- How much does a 3PL WMS cost?

- Which 3PL WMS vendors should you consider?

What is a 3PL warehouse management system (WMS)?

A 3PL WMS is warehouse management software designed specifically for managing 3PL operations. They’re fully equipped to handle complex operations with multiple owners of inventory.

3PL warehouse software also typically can customize things like billings, reporting, and labels to each customer.

What are your 3PL WMS requirements?

Take the overview of your business and expand it out. What does your average day look like? How about your busy season or cyclical inventory needs? Whatever sets you apart from your competition needs to be supported by any 3PL WMS you implement.

In the logistics space, a 3PL thrives on customer service. So, your WMS needs to have modules that support every element of your service, including:

- Shipping and receiving

- Recipe its and invoicing

- Tracking, verification, and auditing

- Data sharing

- Integrating with your CRM, ERP, and other chief software

- The ability to customize individual elements to each customer within the overall system

If your business is like the average 3PL, you’re working with multiple customers and a variety of operational processes and demands. Each comes with its own set of documentation and specific billing practices.

In other words, your requirement should be that the WMS supports your business and automates or eases your most common processes.

Another core requirement needs to be ease of use. You want a system that’s simple and direct so that you’re not wasting time. Most customers will have their quirks and unique demands.

Choose a WMS that allows you to adapt to these without making it burdensome or requiring a Ph.D. in dashboards and user interfaces.

If you don’t think your team can understand it, then walk away. Or else, you risk issues that can delay or miss billing, cutting your margins way too thin.

How to gather your 3PL WMS requirements

It’s easy to say: “I’m going to make a list of my unique needs!” It can get a bit harder when trying to do that. One of the best ways to get your list started is to write down affirmative statements of what you now provide, or want to provide soon, for your customers.

Here are some examples that can get you thinking:

- We track and ensure perishable cargo always remains in specified temperature ranges.

- We deliver countrywide within two business days.

- We use SQL databases to share information with partners and vendors.

- We need workflows that include customer specifications.

- We make billing simple and easy to understand so that we can get paid on time.

- We’re faster than anyone else.

- We guarantee 99% order accuracy.

- We can scale from 20 packages to 20,000 each day for our biggest customers.

- We want to offer 24/7 support and visibility thanks to data and a talented team.

- We want our customers to enjoy working with us.

These types of statements will help you understand the value proposition you bring to your negotiations, and it’ll help you look for areas where a WMS will make a difference.

For example, to maintain 99% order accuracy, you need a system that properly uses your order data to create pick orders and audits the process.

If you want 24/7 visibility, then you’ll need a customer portal or the ability to have customers integrate with your data streams.

And, if you want to be a partner people enjoy working with, then you’ll need a system that’s simple, direct, and doesn’t screw up billing.

What features should you look for in a 3PL WMS?

Always work from your WMS requirements to build out a features list. It’s the best way to ensure you’re making a wise WMS investment to support your business. Here, we’ll take a look at the top five areas of functionality that are important to the modern 3PL warehouse.

Everything always comes back to customers and order management, so keep them as your focus to avoid getting caught by the shiny things offered in some 3PL open-source software options.

Inventory control

Start with the traditional WMS feature set to generate a baseline of your requirements. Inbound controls are a must, as are most standard functions.

3PLs, in particular, will want to look at cross-docking support, appointment settings, vendor scoring, and the ability to process returns as easily as new shipments.

These controls also need to cover asset tracking within your warehouse and on the road. You want to be able to tell, at a moment’s notice, where your trucks and goods are.

You can make this data available to customers as a value-add, or simply track it to monitor your actual costs compared to estimates for each order.

You know the intricacies of 3PL distribution better than anyone, so look for features you need to run your day-to-day operations.

Carrier partners are a huge part of your business. So, look for simplicity when it comes to supporting all the modes you use. Secure common partners like UPS and FedEx as well as local rail and regional delivery options.

Ask about enhanced track and trace capabilities so that you can manage down to the individual SKU level as well as pallets and full loads.

Billing

Core in any 3PL WMS investment is support for your billing needs. 3PLs face some of the most complex billing requirements and demands of anyone in the logistics space. You want a 3PL billing platform that is full of options to meet customer needs.

In the best case, you’ll also want a system that allows you to create unique billing elements for any customer. Some of the more common and potential features include the ability to:

- Capture and charge for value-added services

- Note Inbound and outbound handling charges

- Monitor recurring storage costs

- Split charges, such as storage or initial trial periods

- Support anniversary billing

- Generate reports and charges for activity-based billing — such as through your RF gates and handhelds

- Create 3PL billing reports with breakdowns for each transaction

- Customize key costs recorded for each transaction

- Generate recurring monthly expenses in categories you can configure

- Automatically post invoices to each customer’s general ledger

- Set billing to occur specific to each customer contract

Essentially you want to look for the ability to track and bill revenue for each customer in a way that makes sense for your business. In a 3PL WMS, billing needs to be sophisticated and powerful, but not too confusing for your team.

Analytics and reports

Real-time data is essential to running a lean and efficient operation. You should ask for a 3PL warehouse platform that can monitor and track all of your existing data points plus take input from a variety of sources.

Look for a system that matches your warehouse size, space, and number, plus any that allow you to cross-dock and make the most of the inventory as it arrives.

Analytics should have workforce elements to help you understand individual and shift performance as well as look for better ways to run your business. Today’s 3PL WMS options can help you improve picking lanes and inventory locations based on use and common orders.

Reporting tools need to look at real-time data as well as information from complete jobs. Look for access to standard reports and customizable templates.

It helps to have a system that gives you a variety of permissions so that you can share information with the right partner or employee. This allows people to verify their work and send it to customers without exposing any unnecessary or irrelevant data.

Integration

Building on the carriers we mentioned earlier, the best 3PL software will be able to integrate with carriers and suppliers.

You want a system that will create these connections and put it all on a dashboard to power your team to see available modes and carriers, making a final selection based on price and time.

Some WMS can automate this based on rules, while others can make suggestions and rank lists before you make the final decision. Choose based on what’s most comfortable for you.

Other integrations to consider are any portals your suppliers use, the software you’re running (especially CRMs and ERPs), purchase order management tools, analytics platforms, and the ways you commonly share information.

Importing from Excel documents might be right for you, while others might need a robust API to use and export information for internal reports.

Cloud-based options tend to have a few more integrations, especially with e-commerce tools. However, you should be able to get a cloud or on-premise service that meets your needs.

Specialty elements

Now it’s time to consider the unique factors facing your business in the 3PL space as well as in the overall supply chain. One common system that a WMS for 3PL businesses should have — that you’ll rarely see outside the space — is the ability to monitor ownership transfers.

3PLs need to transfer inventory between owners consistently. Liability, insurance, and other factors come into play during these handoffs and handshakes. Look for a WMS that allows you to record receipts and properly note when goods are accepted.

You’ll want to be able to see the entire chain for each product and shipment, across all of your inbound and outbound processing.

Find the latest WMS pricing information in our free WMS software pricing guide

How much does a 3PL WMS cost?

Now comes the downside of 3PL software that’s open source, cloud-based, or on-premise: no one wants to give you a straight answer when it comes to pricing.

You’ll find data is fairly limited and most companies resist providing online quotes or even pricing estimates based on general profiles.

And that’s because pricing depends on your warehouse, customers, location, shipping lanes you need to support, modules, and more.

That said, there are some generalities we can pull based on what’s available online and the common fees or WMS costs that 3PLs say they are paying. Here are a few things to expect and consider:

- Monthly subscription and license fees tend to be around $500 to $750 or jump up to between $1,000 and $3,000. The difference here is the tier you fall in based on the number of warehouses you have as well as the number of licenses you need.

- Up-front fees, if you go the perpetual license route, will cost you between $20,000 and $60,000, though some large organizations will see it rise even higher. Most small 3PLs will see the cost come in under $50,000, while those with multiple warehouses should expect closer to the $80,000 to $100,000 range.

- Implementation costs range significantly. Cloud systems tend to be cheaper, on the whole, running at around $5,000 when you don’t have any custom integrations. On-premise services tend to be higher, around $10,000 to $30,000 on average because they are tweaked to fit your specific equipment and warehouse layout. Part of the price discrepancy also seems to be a tendency for 3PLs with annual revenues above $50 million to choose an on-premise service, so there’s a correlation between budget, spending, and need.

- If you choose a cloud system but are doing a lot of customization on your systems to support it, you could see costs rise in a way that’s hidden. This is because you’re paying staff their normal wage, but their hours are devoted to creating a 3PL software solution for you. This is likely on top of their regular workload, so you may also risk overtime costs.

- Single-warehouse 3PLs are going to pay slightly higher per-warehouse costs for things like licensing cloud solutions and implementation than a 3PL with three or more warehouses.

- When you move into the range of two to five warehouses, you’re looking at a slight bump in implementation fees and starting to see a preference for on-site solutions, so costs start to rise above $100,000.

These are broad estimates based on published reports from third-party services and aggregators. So, you’ll ultimately be looking at a broad range of pricing and want to get plenty of options from an RFP to see where you’ll stand.

Highlight your must-haves and the features you’d like to get a good handle on pricing differences.

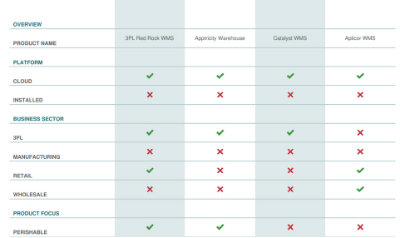

Which 3PL WMS vendors should you consider?

Creating a WMS comparison list is the right way to start seeing what’s available for your industry and your budget. That said, there are a few vendors we’ve previously highlighted as top competitors in the 3PL space.

Here’s a shortlist of some of the best 3PL software to get you started:

3PL Central’s 3PL Warehouse Manager is designed for 3PLs and omnichannel order management. It has robust customization tools for various customer billing and provides automation to help 3PLs operate more efficiently.

Scalability and integration earn Aptean high marks with its customers, especially as they grow from a single warehouse to multiple. It’s one of the few that we received recommendations for from companies of a wide range of sizes and locations.

Accuplus 3PL WMS is the ideal 3PL software for small businesses. It’s an easy-to-use, comprehensive WMS with the ability to manage multiple warehouses and documentation while providing a variety of useful and well-laid-out reports.

Customer visibility and event management are truly at the heart of the design.

The company focuses on real-time data that are especially useful for 3PLs. It has a specific 3PL-branded version that includes a variety of benefits and features like tariff groups, location management, custom 3PL billing, and integration with manufacturer tools and portals.

If you have existing software packages that you need to keep, Cin7’s range of 3PL software solutions might be the right choice. It has a large emphasis on integration, and many customers might be using its modules already.

In our list, it’s among the best at handling custom EDIs, so you can bring your existing tracking and reporting with you to the new WMS. Cin7 provides sleek, efficient 3PL software for small businesses right up to multi-location enterprises.

Cin7's dashboard view